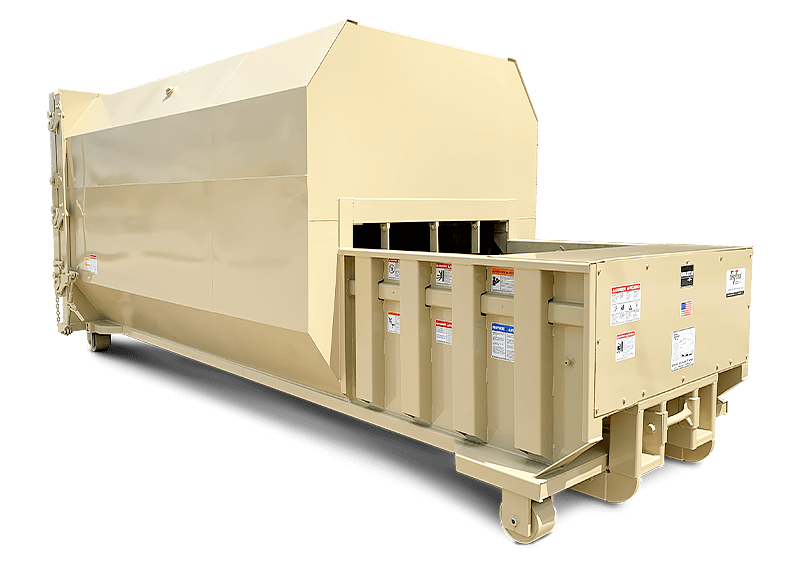

Self-Contained Compactors

The most widely used wet-waste compactor in the industry. Found at grocery stores, hospitals, apartment complexes, restaurants, universities, and stadiums.

Self-contained compactors feature a permanently joined compactor and receiver box for compaction, emptying, and minimizing leakage. If your business deals with food waste, wet waste, or granulated materials that could leak when separating a container from the compactor, then you should consider a self-contained compactor.

Self-contained compactors come in a large variety of shapes, sizes, and compaction power. These machines are designed to store and transport wet wastes. Waste Equipment Rentals & Sales' compactors reduce commercial waste cost by cutting down on the number of times the container needs to be hauled.

Self-Contained Compactors are Ideal for:

- Retail

- Manufacturing

- Healthcare

- Apartments

- Restaurants

- Grocery

- Industrial

- Hotels

- Malls

Self-Contained Compactors Available

To discuss which of our self-contained compactors or dual recycling compactors would be best for your industry, fill out our online contact form or call us at (833) 233-9377.

Key Features and Benefits:

- Exclusive 41 inch and 58 inch feed opening to handle large, bulky items

- Overall Length: 171 inches

- Overall Height: 89 inches

- Continuous feeding capability - even while the compactor is operating

- Up to 24 tons of crushing force to reduce refuse to a fraction of it's former size, saving valuable space and reducing landfill trips

- Perfect for: Apartment Communities, Malls, Shopping Centers, Dairies, Large Restaurants, Cafeterias, Fast Food, Airline Food Service, Supermarkets, Food Processors, Theme Parks, Resorts, Hospitals, Institutions, and Hotels

Key Features and Benefits:

- Exclusive 41 inch by 58 inch feed opening to handle large, bulky items

- Overall Length: 208 inches

- Overall Height: 89 inches

- Continuous feeding capability - even while the compactor is operating

- Up to 24 tons of crushing force to reduce refuse to a fraction of its former size, saving valualbe space and reducing landfill trips

- Perfect for: Apartment Communities, Malls, Shopping Centers, Dairies, Large Restaurants, Cafeterias, Fast Food, Airline Food Service, Supermarkets, Food Processors, Theme Parks, Resorts, Hospitals, Institutions, and Hotels

Key Features and Benefits:

- Exclusive 41 inch by 58 inch opening to handle large, bulky items

- Overall Length: 214 inches

- Overall Height: 104 inches

- Continuous feeding capability - even while the compactor is operating

- Up to 24 tons crushing force to refuse to a fraction of its former size, saving valuable space and reducing landfill trips

- Perfect for: Apartment Communities, Malls, Shopping Centers, Dairies, Large Restaurants, Cafeterias, Fast Food, Airline Food Service, Supermarkets, Food Processors, Theme Parks, Resorts, Hospitals, Institutions, and Hotels

Key Features and Benefits:

- Exclusive 41 inch by 58 inch feed opening to handle large, bulky items

- Overall Length: 245 inches

- Overall Height: 104 inches

- Continuous feeding capability - even while the compactor is operating

- Up to 24 tons crushing force to refuse to a fraction of its former size, saving valuable space and reducing landfill trips

- Perfect for: Apartment Communities, Malls, Shopping Centers, Dairies, Large Restaurants, Cafeterias, Fast Food, Airline Food Service, Supermarkets, Food Processors, Theme Parks, Resorts, Hospitals, Institutions, and Hotels

Key Features and Benefits:

- Exclusive 41 inch by 58 inch feed opening to handle large, bulky items

- Overall Length: 269 inches

- Overall Height: 104 inches

- Continuous feeding capability - even while the compactor is operating

- Up to 24 tons crushing force to refuse to a fraction of its former size, saving valuable space and reducing landfill trips

- Perfect for: Apartment Communities, Malls, Shopping Centers, Dairies, Large Restaurants, Cafeterias, Fast Food, Airline Food Service, Supermarkets, Food Processors, Theme Parks, Resorts, Hospitals, Institutions, and Hotels

Key Features and Benefits:

- Exclusive 41 inch by 58 inch feed opening to handle large, bulky items

- Overall Length: 299.5 inches

- Overall Height: 104 inches

- Continuous feeding capability - even while the compactor is operating

- Up to 24 tons crushing force to refuse to a fraction of its former size, saving valuable space and reducing landfill trips

- Perfect for: Apartment Communities, Malls, Shopping Centers, Dairies, Large Restaurants, Cafeterias, Fast Food, Airline Food Service, Supermarkets, Food Processors, Theme Parks, Resorts, Hospitals, Institutions, and Hotels

Key Features and Benefits:

- Exclusive 41 inch by 58 inch feed opening to handle large, bulky items

- Overall height with hydraulic tailgate raised: 16 feet 6 inches

- Up to 24 tons crushing force to reduce refuse to a fraction of its former size, saving valuable space

- Perfect for weekly volumes of more than 100 cubic yards at wet or general waste materials

- Perfect for: Apartment Communities, Malls, Shopping Centers, Dairies, Large Restaurants, Cafeterias, Fast Food, Airline Food Service, Supermarkets, Food Processors, Theme Parks, Resorts, Hospitals, Institutions, and Hotels

- Great for waste with high liquid content

- Perfect for weekly volumes of more than 100 cubic yards of wet or general waste materials. All models have a packer head with integral cart dumping mechanism permanently attached to the containter

- Exclusive 41 inch by 58 inch feed opening to handle large, bulky items

- Up to 24 tons crushing force to reduce refuse to a fraction of its former size, saving valuable space

- Perfect for: Apartment Communities, Malls, Shopping Centers, Dairies, Large Restaurants, Cafeterias, Fast Food, Airline Food Service, Supermarkets, Food Processors, Theme Parks, Resorts, Hospitals, Institutions, and Hotels

Rental. Sales. repair

Explore More Compactors

Can’t find what you are looking for? We have a compactor for your specific needs depending on your type of waste, volume, and facility layout.

Stationary Compactors

The most widely used dry-waste compactor in the industry

Augers & PreCrushers

Augers and PreCrushers are great compact solutions for tougher applications.

Apartment & Vertical Compactors

Compact compaction systems ideal for locations where space is limited.

Latest News

Check out our blog to discover the latest industry trends and Waste Equipment Rental & Sales updates.

Join Our Growing Team

Waste Equipment is currently searching for qualified applicants for open Field Service Technician positions…

Read More

How Does Your Compactor Work?

Have you ever wondered how your compactor works? A compactor consists of five basic components. The body,…

Read More

Handling Waste

Recently a health clinic was fined over $25,000 for the mishandling of hazardous waste. A spokesperson…

Read More24/7 Service You Can Count On From Coast to Coast

Simply fill out the fields below and a Waste Equipment Rentals & Sales Associate will contact you shortly.

Waste Equipment Rentals & Sales is committed to delivering the absolute highest quality of servicing to clients ranging from local businesses to national chains and Fortune 500 companies. Our team is dedicated to its mission to bring service back to the service industry by delivering unrivaled customer service each and every day.