Horizontal Balers

The prime solution for recyclers looking to save time, money, and space with their products.

Increase your recycling and profitability.

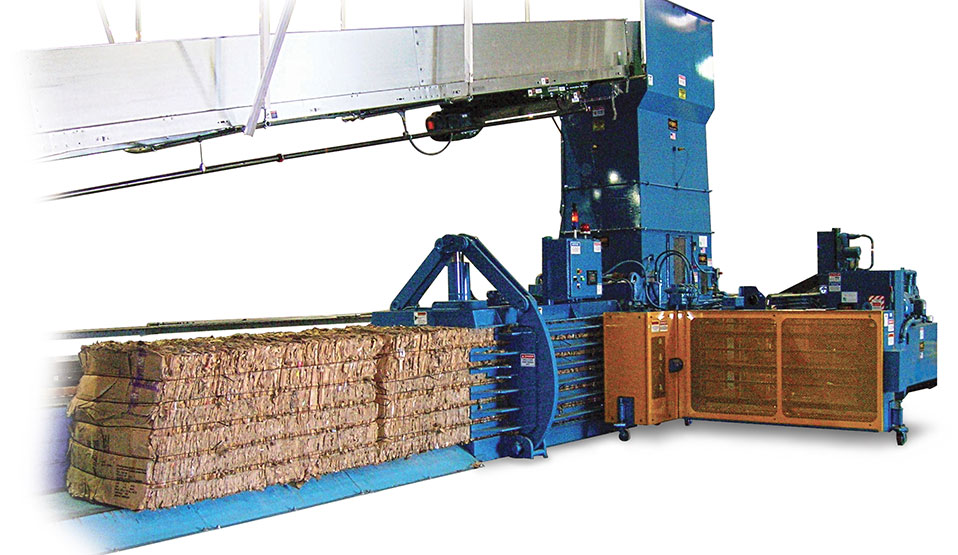

Horizontal balers are a great solution designed for high productivity and large generators of recyclable materials in industrial, commercial, and manufacturing applications. Waste Equipment Rentals & Sales can help your company from determining the best baling machine for your needs to sourcing a buyer for the recyclable bales, including manual tie, auto tie balers, and closed-end horizontal balers. We have a recycling solution for every type of commodity and price point, providing flexible solutions to meet everyone's needs including the following:

- Customized Lease Options

- Purchase Options

- Equipment Consulting and Design

- Installations and Removals

- Full Preventative Maintenance Programs

- 24/7 Repair Services

Horizontal Balers Available

Key Features and Benefits:

- Options: Non-ferrous, Closed-End, Side Eject

- Wide variety of feed openings available to accommodate your specific material size

- Compatible with conveyor, chute, cart dumper, or hand-feed applications

- Processes a variety of materials

- Hydraulic Bale - Door Release

- Full- Penetration Ram for Maximum Compaction and full-bale ejection

- Wire Guides for Quick and Easy Ties

Key Features and Benefits:

- Replaceable serrated body and ram shear blades

- Equipped with single-cylinder bale tensioning system

- Spring-loaded retainer locks, adjustable wire positioned, and adjustable inserted needle postioners

Waste Equipment Rentals & Sales Auto-Tie Horizontal Baler uses highly efficient gear twisters, which eliminates pigtails. This accounts for more than 10% reduction in wire consumption and related costs. The gear twisters and inserter needles are hydraulically driven and the wire is dispensed directly from our unique box holders. Hydraulic wire positioners precisely align the wires for pick-up by the inserter needles, making our model the most reliable on the market.

Our Auto-Tie Balers are designed for high productivity and ease of use with advanced electronics, such as the color touch-screen operator interface. From this interface, the operator can control a variety of baler functions such as auto and manual modes, bale settings, system pressure, bale length, and perform computerized diagnostics. The main panel box features IEC controls.

Key Features and Benefits:

- Full-penetrating compression ram for high-density bales

- Programmable PLC controller with automatic and manual controls, diagnostics, and bale set-up functionality

- Multi-purpose door serves as a bale separator, bale release, and bale clamp, as well as allowing for variable bale widths

- Optional metal packages for scrap processing and recycling applications

- Perfect For: Stations/Municipal, Thrift Stores, Theme Parks, Education, Logistics/Distribution Centers, Big Box Stores, Industrial Manufacturing

Latest News

Check out our blog to discover the latest industry trends and Waste Equipment Rental & Sales updates.

Join Our Growing Team

Waste Equipment is currently searching for qualified applicants for open Field Service Technician positions…

Read More

How Does Your Compactor Work?

Have you ever wondered how your compactor works? A compactor consists of five basic components. The body,…

Read More

Handling Waste

Recently a health clinic was fined over $25,000 for the mishandling of hazardous waste. A spokesperson…

Read More24/7 Service You Can Count On From Coast to Coast

Simply fill out the fields below and a Waste Equipment Rentals & Sales Associate will contact you shortly.

Waste Equipment Rentals & Sales is committed to delivering the absolute highest quality of servicing to clients ranging from local businesses to national chains and Fortune 500 companies. Our team is dedicated to its mission to bring service back to the service industry by delivering unrivaled customer service each and every day.